When it comes to handling and moving fluids in the industrial, chemical and pharmaceutical sectors, choosing the right centrifugal pump has important repercussions on the safety, reliability and operational efficiency of the entire plant.

At CDR Pompe, we have built a solid Italian and international reputation over time, thanks to a rigorous approach to design, highly specialised production and ongoing technological research focused on innovation and a sustainable economy.

One of our company’s distinctive elements is the possibility of offering highly customised solutions, tailored to the specific applications and operating conditions of each individual customer. Thanks to a qualified technical department and cutting-edge production facilities, the company is able to design custom centrifugal pumps, in various construction configurations and materials, always ensuring high performance and long-lasting durability, even in the most demanding applications.

What a centrifugal pump is and how it works

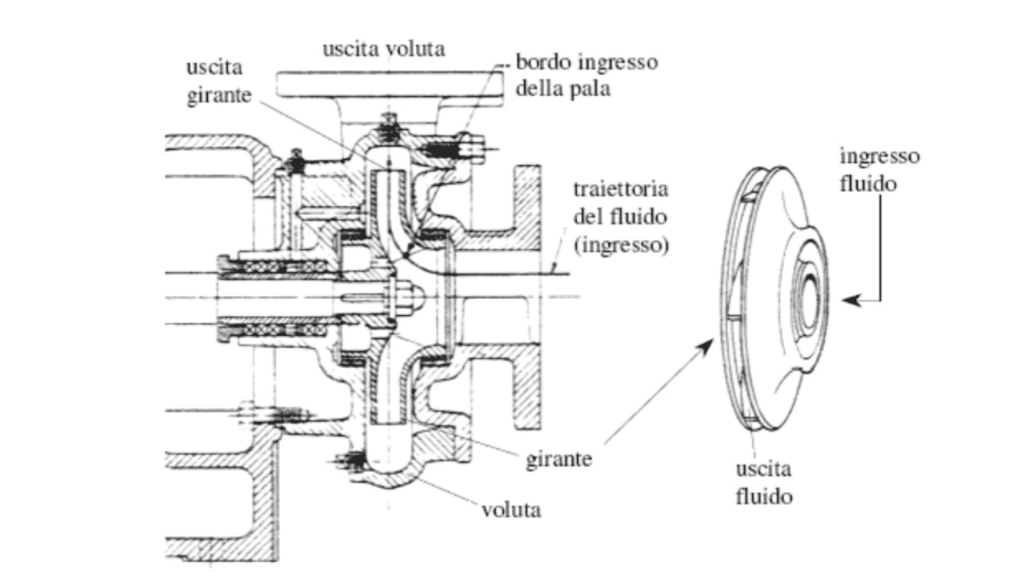

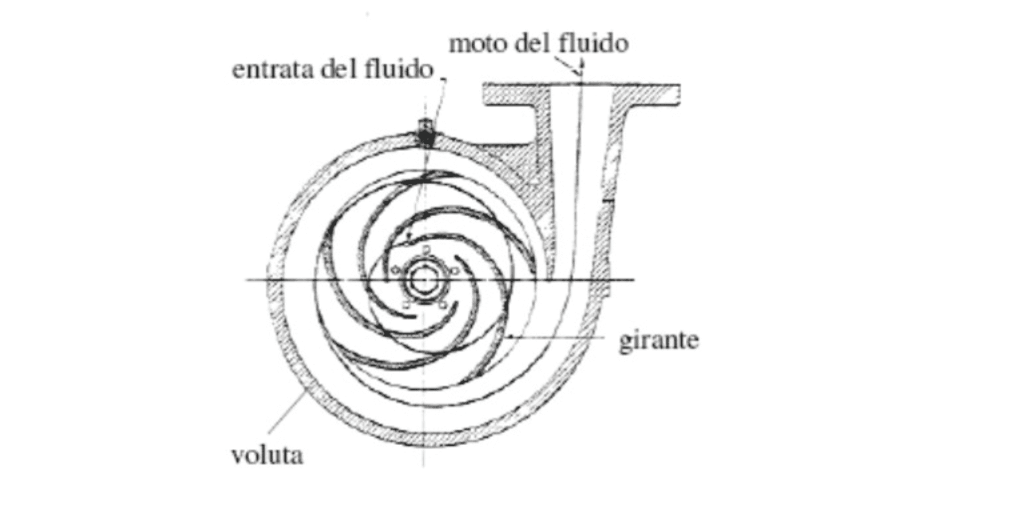

A centrifugal pump is a fluid dynamic device that uses mechanical energy provided by an electric motor to move a fluid. The operating principle is based on the centrifugal effect generated by the rotation of an impeller, a bladed wheel that draws the liquid in from the centre (axial suction) and pushes it towards the periphery (radial or tangential discharge).

During this process, the mechanical energy is initially converted into kinetic energy by the movement of the impeller, and is then transformed into pressure energy inside the pump casing, or volute, which has a progressively expanding cross-section.

More specifically, the impeller, rotating at high speed, generates a low-pressure zone at the pump inlet, thus facilitating suction of the liquid from the upstream circuit. The fluid, intercepted by the curved blades of the impeller, gains speed as it is drawn towards the periphery of the impeller itself, under the action of the centrifugal force. Once the outer edge is reached, the liquid is expelled with a certain speed and directed into the volute, a chamber with a progressively widening shape that slows down the flow and transforms the remaining kinetic energy into pressure energy. This increase in pressure allows the fluid to overcome the resistance of the delivery circuit and reach the point of use.

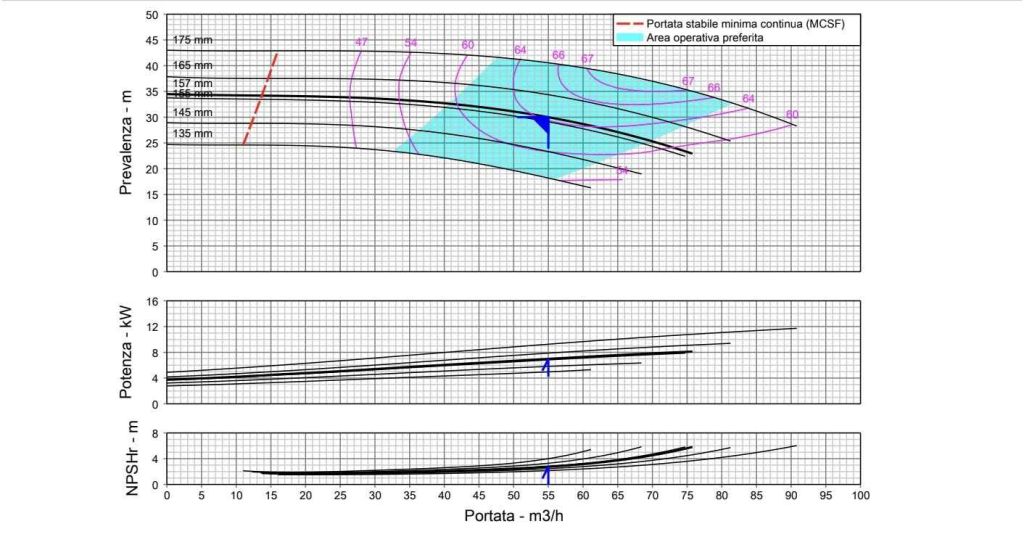

The performance of this process is determined by the pump’s performance curve, which represents the relationship between the delivered flow rate and the developed head, two essential parameters for the correct selection and configuration of a centrifugal pump based on specific plant requirements. The closer the operating point is to the centre of the curve, the better the performance will be in terms of efficiency, energy savings and pump longevity.

Compared to the volumetric pumps and peripheral pumps discussed in previous articles, centrifugal pumps are more efficient in high flow applications.

The main components of a centrifugal pump

The structure of a centrifugal pump consists of several essential elements, each with specific functions and designed to ensure efficiency and durability over time. Specifically, the main components of a centrifugal pump that have a direct influence on performance and that undergo continuous technological evolution by our Research and Development department are:

- Impeller: this is a bladed wheel that has the task of transferring mechanical energy to the fluid. It can be of various types (closed, open, single-channel, recessed, vortex) depending on the required flow rate and pressure.

- Casing (or pump body): this is the casing that contains the fluid and directs the flow from the impeller to the discharge. It is specifically designed to withstand high pressures and temperatures.

- Volute: consists of a spiral-shaped section of the pump casing with an increasing cross-section, essential for efficiently converting mechanical energy into hydrodynamic energy

- Shaft: this connects the impeller to the motor, transmitting the power necessary for rotation.

Factors influencing the choice of a centrifugal pump for your company

The Sales Department and the Technical Department at CDR are always available, with dedication and professionalism, to advise the customer in choosing the right centrifugal pump for their system’s specific needs. As we have mentioned, this type of pump has many different variants (open or closed impeller, horizontal or vertical, magnetic drive or mechanical seal), and as a result, various parameters must be considered before installation, including:

- Fluid temperature: in the event of high temperatures, materials that can withstand heat and adequate cooling systems are required. For temperatures above 65°C, for example, it is important to maintain adequate inlet pressure to avoid cavitation; conversely, in the event of extremely low temperatures (-100°C), CDR offers stainless steel configurations suitable for working in these environments;

- Flow rate and head requirements: the characteristics of the system determine the specifications of the pump necessary to meet the flow and pressure needs;

- Suction conditions: suction height, available pressure and NPSH (Net Positive Suction Head) are essential to avoid cavitation phenomena, which can damage the pump;

- Mechanical installation: position of the shaft (horizontal or vertical), type of foundation, type of motor-pump coupling (direct or with joint), and pipe layout;

- Safety regulations and certifications: in environments with potentially explosive atmospheres (ATEX) or for toxic fluids, it is necessary to use certified pumps with specific sealing systems;

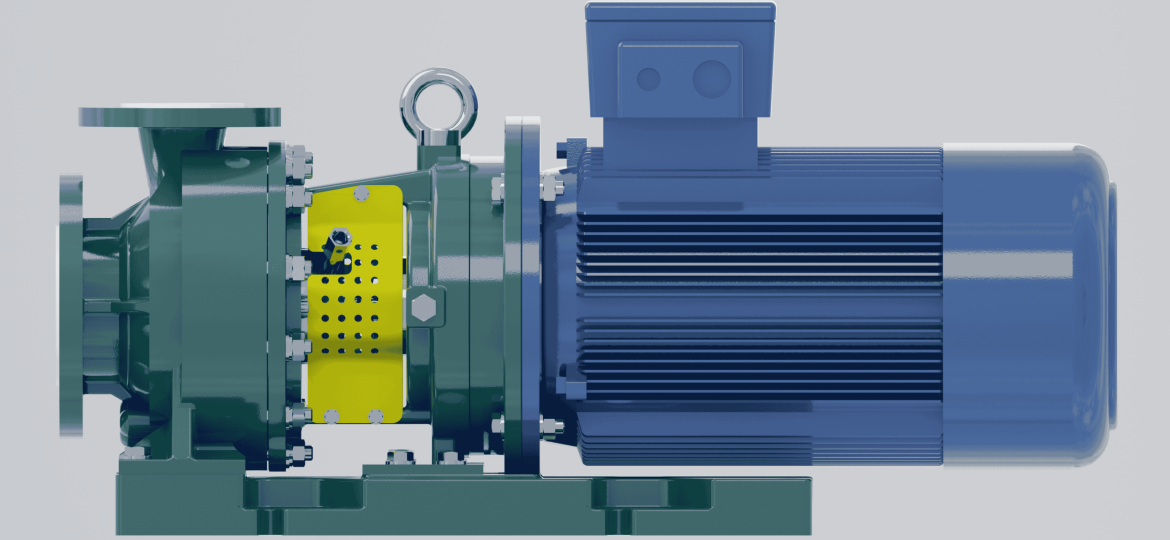

- Maintenance and accessibility: pumps with back pull-out allow for maintenance without disassembling the pipes. This should be evaluated based on the type of system in which the centrifugal pump will be installed;

- Presence of suspended solids: in cases of flows containing solid particles, appropriate impellers and designs are required to prevent clogging and wear of the product.

CDR’s range of centrifugal pumps: advanced technology for critical applications

CDR Pompe offers a comprehensive and highly specialised range of centrifugal pumps, designed to meet the most complex needs of industrial plants with high flow rates and critical operating conditions. The product range includes mechanical seal and magnetic drive pumps, available in various horizontal and vertical configurations and made from materials carefully selected to ensure chemical and mechanical resistance.

Magnetic drive pumps are the pride of CDR’s production, in which the rotary motion is transmitted to the impeller via a magnetic coupling. By eliminating the need for a mechanical seal, the risk of leakage and contamination is greatly reduced. As a result, this technology is ideal for corrosive, toxic or hazardous fluids, where safety and reliability are of paramount importance. The parts in contact with the fluid are made of stainless steel or technical thermoplastic materials such as PP, PVDF or PFA, selected based on the nature of the liquid to be handled.

CDR centrifugal pump ranges

Depending on the type of plant and the customer’s operational needs, CDR’s range of centrifugal pumps is divided into 4 categories:

- Mechanical seal horizontal pumps: single-stage, complying with ISO 2858 and ISO 5199, also available with ATEX certification for use in potentially explosive environments.

- Magnetic drive horizontal pumps: with wetted parts in stainless steel or plastic materials, designed for direct installations on pipelines and for applications with aggressive or extremely hazardous fluids.

- Magnetic drive vertical pumps: custom made, with parts in contact with the fluid in PVDF, suitable for low NPSH conditions and extremely hazardous fluids.

- Custom pumps: design and manufacture of custom vertical and horizontal centrifugal pumps for critical applications, with customised materials and configurations.

This wide range allows CDR Pompe to provide optimal solutions for every type of system, ensuring high performance, safety and durability even in demanding operating conditions. The possibility of choosing between versions in steel or lined in PP, ETFE, PVDF or PFA allows the pump to be adapted to the specific chemical and physical characteristics of the fluid, ensuring maximum compatibility and protection against wear and corrosion.

The CDR centrifugal pump represents a top-of-the-range solution for high flow applications, thanks to its combination of advanced technology, high-quality materials and a comprehensive range that covers every industrial need. Thanks to a team of experts and a global distribution network, the company is able to support customers at every stage, from product selection to after-sales maintenance.

For all the information you need, visit our website and make an appointment!