Chemical pumps are one of the flagship products of CDR‘s production. We offer a wide range of products suitable for working in contact with toxic, corrosive and acidic fluids.

The safety of workers and systems in hazardous environments and respect for the environment and the circular economy are two aspects on which CDR Pompe places great importance. Thanks to over a decade of experience and a constant commitment to innovation and research, our company excels in both aspects, ensuring safe products for people, for companies and for the ecosystem.

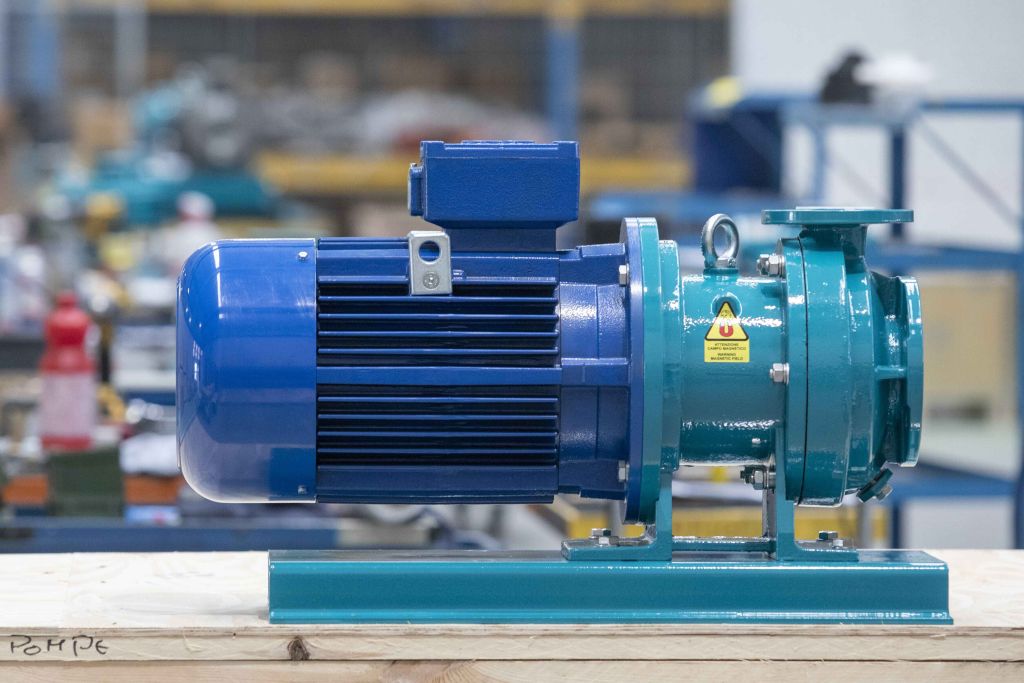

The high danger of the chemical sector requires very high standards in terms of efficiency and safety. Magnetic drive centrifugal pumps and mechanical seal centrifugal pumps are the two ranges that we consider most suitable for these types of processes.

Fluids in chemical environments: coordination and safety come first

When dealing with hazardous, corrosive or explosive fluids, it is essential to handle them as safely and efficiently as possible. CDR chemical pumps have been designed to deal with these situations with the utmost precision and reliability. Thanks to the use of cutting-edge technologies in the sector, leakage-free fluid transfer is guaranteed. This feature of our products always maintains the safety of the system at the highest levels. CDR pumps can be adapted to the specific requirements of different types of fluids, ensuring that every application receives the utmost attention and care. This is also guaranteed by the numerous certifications we have obtained for chemical environments, such as the ISO 2858 and ISO 5199 Standard and FDA certification.

When it comes to very complex work systems, it is crucial to find the correct pump configuration for each customer. CDR pumps can be configured to meet the specific needs of the various fluids. This ensures that every application is treated with the utmost care and attention. What is needed is a customised approach based on the characteristics of the work required, as it is essential to assess the chemical compatibility of the pump, in addition to many other factors that are crucial for selecting the right product.

There are many liquids used in the chemical sector, and our pumps must therefore be able to work effectively for all types of fluids. Specifically, the most commonly used are centrifugal pumps for sulphuric acid, pumps for hydrofluoric acid, pumps for caustic soda, pumps for hydrochloric acid and pumps for ammonia.

CDR chemical pumps: products that last, while respecting the environment

CDR Pompe is investing heavily in research, environmental safety and the green economy.

Our pumps have been designed to minimise energy consumption as much as possible. In this way, we aim to produce a smaller ecological footprint while also saving on operating costs. CDR has always operated with a long-term perspective and focuses on an increasingly green approach, offering the customer the best choice in terms of durability and energy efficiency.

Our approach to protecting the environment starts at the design stage. Our chemical pumps are designed to minimise environmental impact through technologies that reduce emissions and fluid losses. Products made for the chemical sector are designed with a watertight construction and through the use of materials resistant to corrosion and chemical agents. These features ensure that the pumps can operate efficiently without causing environmental damage.

Our commitment to safety allows CDR centrifugal pumps to work effectively even in very critical conditions. In fact, almost all of our products are suitable for installation in ATEX environments, to work in potentially explosive atmospheres, guaranteeing maximum safety and quality on the market.

In addition, they can be installed both indoors and outdoors, exposed to atmospheric agents, while maintaining the highest possible level of efficiency and safety.

Magnetic drive pumps: perfect for chemical environments

Especially when it comes to the chemical sector, we recommend the purchase of magnetic drive centrifugal pumps to the customer whenever possible. This is not only because we want to offer a superior quality product, but especially because it significantly increases safety in the system.

The principle of magnetic drive is in fact revolutionary. An external magnetic core drives the internal magnetic core without direct contact but only by means of an attraction/repulsion mechanism of permanent magnets. A containment shell ensures complete isolation from the external environment.

The total absence of a mechanical seal means that magnetic drive pumps do not leak in the event of breakage. In addition, the costs of ordinary maintenance compared to mechanical seal pumps are practically halved. This means greater safety for the system and reduced maintenance costs.

Thanks to its commitment to innovation and research, CDR Pompe is a leader in the process pump sector. We design solutions for the handling of fluids not only in chemical environments, but also in industrial and pharmaceutical settings. 2025 is also set to be a year of great developments and expectations, as we continue to pursue the green path that represents a fundamental commitment for us. Visit us on the website, or write to us for information about our products.