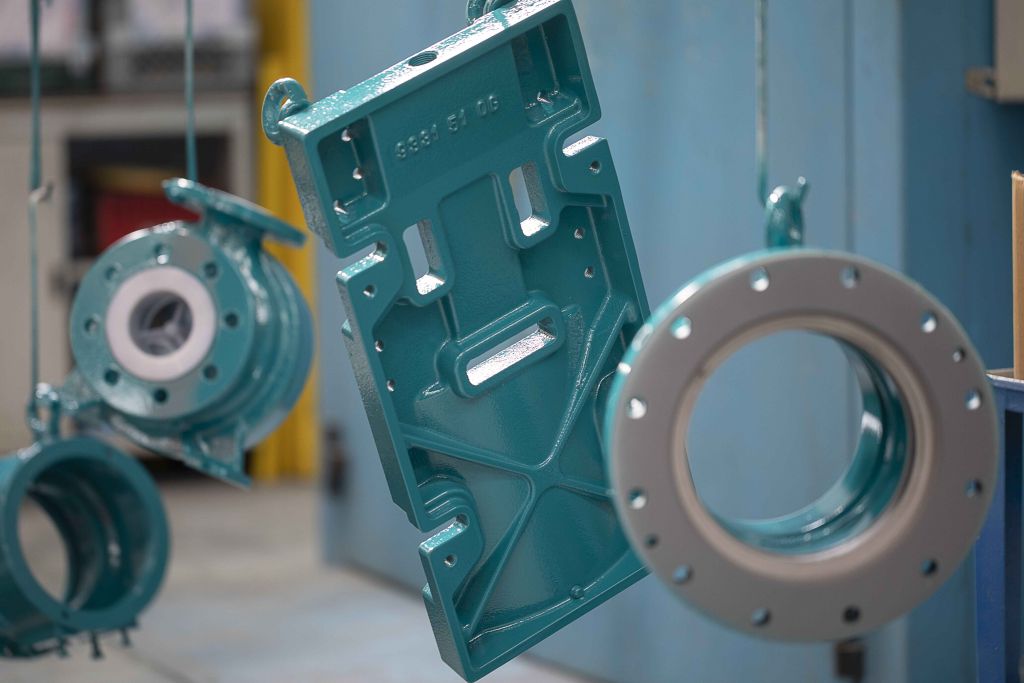

Our lined pumps are made with transfer moulding technology and are a key part of CDR production for chemical and pharmaceutical applications.

These are essential devices for transporting highly corrosive or abrasive fluids: their internal coating in thermoplastic or elastomeric materials guarantees chemical and mechanical resistance, increasing the operating life of the equipment.

The technique of transfer moulding

Transfer moulding is a technique that combines elements of compression and injection moulding. The polymeric material is first heated in a separate chamber and then forced into a closed mould through a system of channels.

The main result of this method is a thick coating, ensuring superior vacuum resistance compared to other moulding technologies such as roto moulding, or rotational moulding, which instead uses heat and rotary movement to evenly distribute the plastic material inside a mould.

Compared to plastic pumps with components made “from solid” or produced using the injection moulding technique, lined pumps made with transfer moulding guarantee greater dimensional stability at various temperatures, as well as greater resistance to pressures and loads applied to the suction and discharge flanges. In addition, this method reduces the risk of voids or inconsistencies that could compromise the chemical resistance of the product.

It is therefore a process that requires advanced technologies and guarantees maximum quality in the most critical environments, where total fluid isolation is required, even in the most delicate parts of the system.

CDR lined pumps: products of the highest quality and safety

The importance of lined pumps in the chemical and pharmaceutical sector has led us to create them for both mechanical seal and magnetic drive technology. This allows us to meet the needs of both customers who require the pumping of slightly contaminated liquids or those with suspended particulate matter, and customers who require more critical and delicate applications, where the safety and reliability of the system are a top priority:

For mechanical seal technology, CDR Pompe has two models:

- CCL/CCL-B, with closed impeller, features a lined coating of the wetted parts in PP (Polypropylene);

- UCL, a single-stage mechanical seal process pump coated in plastic and fluoroplastic material. This model is also available in PP (polypropylene), PVDF (polyvinyl fluoride) and PFA (perfluoroalkoxy).

For magnetic drive pumps, on the other hand:

- ETN-EVO, Sub-ISO 2858 compliant single-stage magnetic drive pump coated in plastic and fluoroplastic material, ideal for pumping aggressive and hazardous liquids;

- UTN, with closed impeller and horizontal execution;

- DTN range (DTN ASME and DTN ISO), whose new dynamic shaft design guarantees greater pump reliability and lower axial thrust.

The advantages of CDR lined pumps

Compared to traditional pumps, CDR lined pumps made with the transfer moulding technique offer a series of clear and verifiable advantages.

First of all, they have very high chemical resistance. In fact, the materials with which they are designed (PP, PVDF, ETFE and PFA) guarantee exceptional resistance to aggressive chemicals, such as strong acids, bases and solvents. This prevents both corrosion and deterioration of the product, extending its useful life and reducing the risk of issues and the need for routine maintenance.

As we have explained in this article, in the pharmaceutical and fine chemical industry it is essential to avoid product contamination. Plastic coatings offer enormous advantages in this regard, as they guarantee non-reactive surfaces, preventing contamination and meeting high standards of purity.

The pharmaceutical and chemical sectors, as we have explained, are very particular due to the delicate nature of the substances involved. In addition to preventing contamination, another key principle is to prevent leaks as much as possible. Combined with magnetic drive technology, a lined pump made with transfer moulding guarantees a very high level of safety for both operators and work environments.

Finally, a further advantage of lined pumps is their exceptional resistance to high temperatures and pressure: the plastic coating in contact with the process is applied to a mechanically resistant part of the pump, such as pump casings where the mechanically resistant part is made of cast iron.

From chemicals to water treatment: lined pumps are ideal for a variety of industries

CDR lined pumps, made with transfer moulding, have unique characteristics in terms of chemical and mechanical resistance.

This is why they are used in some sectors of the chemical industry, such as the production of acids, solvents and synthesised products, areas for which operational safety and respect for the environment are crucial factors. In the petrochemical industry, which produces semi-finished products primarily derived from methane or hydrocarbons obtained from the petroleum distillation, CDR lined pumps are essential in the handling processes of dangerous substances.

At CDR we have acquired extensive experience not only in the chemical sector, but also in the design of versatile and high-performance pumps for water treatment. Our know-how has allowed us to create ranges of lined pumps suitable for the needs of this extremely delicate sector, such as wastewater handling, drinking water treatment and aggressive fluid management.

Another field that requires attention to contamination and fluid leakage is the pharmaceutical industry, which is characterised by the use of high-value fluids essential for the production of drugs and treatments that require the highest degree of purity and precision. For synthesis processes and the transfer of pure substances, lined pumps ensure efficiency, quality and an exceptionally high standard of safety.

CDR lined pumps made with the transfer moulding technique are an ideal choice for handling corrosive and high-purity fluids, while ensuring high performance, protection and resistance. Their use helps to reduce management and maintenance costs, optimising the efficiency of the system.

Choose CDR for the construction of process pumps for your company. As a leader in the sector, we guarantee continuous assistance, maintenance and the highest quality products.