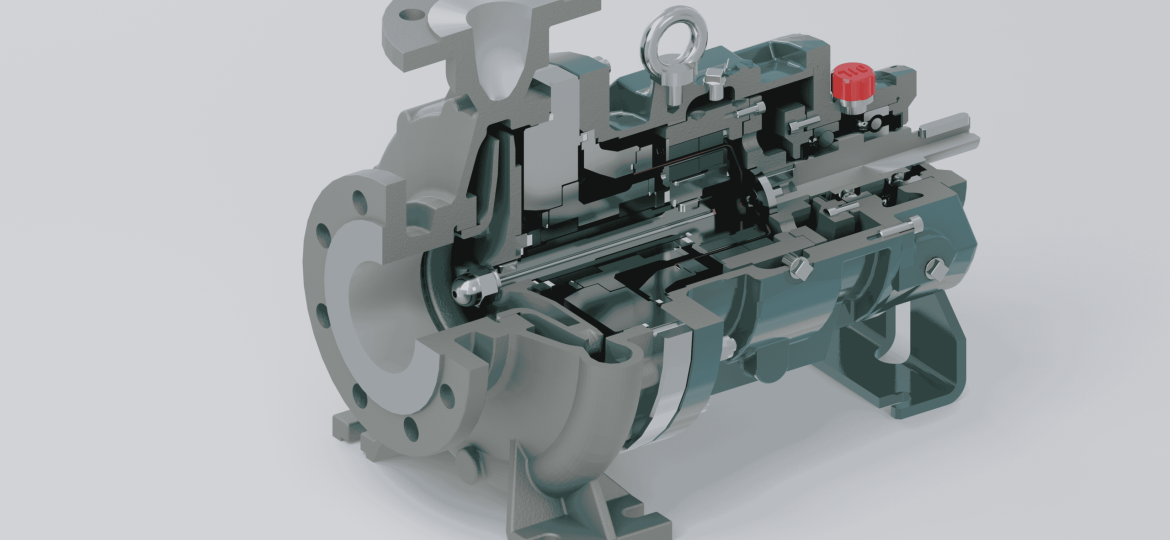

As critical elements in the transfer of fluids in sectors such as chemical, petrochemical, and water treatment, companies are not only responsible for choosing a good pump, but also for anticipating signs of wear, predicting critical scenarios, and ensuring optimal operating conditions. Typical failures in a centrifugal pump—such as dry running, cavitation, and shut off—are not merely accidental events; they are symptoms of mechanical, thermal, or hydraulic imbalance, often stemming from non-optimized plant design, lack of monitoring systems, or out-of-spec operating cycles.

A thorough analysis of these operational issues means learning to prevent them with technical precision, avoiding the progressive degradation of impellers, seals, bushings, and magnetic supports. It also means designing smarter systems capable of protecting themselves through the integration of sensors, advanced materials, and electronic controls.

At CDR, we are well acquainted with the typical failures of a centrifugal pump, and our teams are constantly working to ensure increasingly safe, robust, and efficient products.

Typical Failures in a Centrifugal Pump: Criticalities and an Integrated Prevention Approach

It’s important to know that these failures (dry running, cavitation, and shut off) often do not occur as isolated phenomena.

For example, a plant subject to cavitation may experience dry running due to the resulting lack of circulating liquid in the system. Likewise, a malfunction in the suction valve may create conditions that lead to dry running.

The best form of prevention for any technical or mechanical failure lies in accurate design and continuous monitoring of the system. The use of level detection and power consumption monitoring systems, as well as bypass valves, constitutes a structured strategy to prevent uncontrolled increases in pressure, temperature, consumption, and internal degradation.

Dry Running: Why It’s a Problem and How to Prevent It

Dry running is one of the most common centrifugal pump failures. It occurs when the pump operates without liquid or with inadequate lubrication. Under these conditions, the pump loses the necessary cooling, and the internal components—normally lubricated—suffer direct friction, leading to overheating.

Most pumps, including CDR models, are not designed for this condition: although some configurations with excellent tolerance—such as diamond-coated silicon carbide or graphite—can withstand brief episodes without liquid, they are not substitutes for proper system design and usage.

Typical consequences include increased power absorption up to thermal tripping, deformation of internal plastic components, and in severe cases, the breakage of the bushing itself due to extreme friction. Prolonged dry running can ultimately lead to complete pump failure.

To prevent serious issues like dry running, it is essential to integrate control systems such as discharge pressure gauges, flow meters, and level switches to detect the absence or shortage of fluid. Additionally, the installation of wattmetric relays adds another layer of protection by detecting abnormal increases in power consumption—an early indicator of dry running.

Cavitation: The Invisible Degradation That Undermines Efficiency

Cavitation is one of the most dangerous failures for a centrifugal pump. It occurs when pressure in the suction line drops below the vapor pressure of the fluid, causing vapor bubbles to form. As pressure increases, these bubbles implode, generating micro-shocks that are highly erosive to internal components. Cavitation can result in severe vibration and a significant drop in operational efficiency, with major impacts on flow rate and head. Structurally, these implosions can erode the impeller blades and damage seals and housings, leading to sudden and costly breakdowns.

One of the most effective ways to prevent and manage cavitation is to rely on the NPSH (Net Positive Suction Head) parameter. The ideal condition is for the available NPSH (NPSHa)—determined by pressure at the suction point, pipe losses, and fluid temperature—to consistently exceed the required NPSH (NPSHr) of the pump. To ensure this margin, solutions range from reducing suction pipe head losses to optimally positioning fluid sources (e.g., elevated tanks), and even integrating boosters or inducers.

Shut Off: The Hidden Failure Caused by a Closed Valve

Shut off, or the closing of the discharge valve while the pump is running, is another typical centrifugal pump failure that can lead to serious malfunctions. In this condition, the fluid—unable to exit the discharge line—starts to recirculate internally within the pump. This results in increased internal temperature and the gradual vaporization of the liquid. It may be caused by:

- Closing the discharge valve during pump operation;

- Head loss on the discharge line exceeding the pump’s developed head.

Although the effects are not as immediate as dry running, the end result is similar: overheating and loss of lubrication damage plastic components, while seals and bushings gradually fail and eventually break. Implementing a bypass or pressure switch is one of the most effective technical-structural solutions to prevent irreversible damage.

CDR Pompe: Reliability, Expertise, and Innovation Against Common Pump Failures

Thanks to an advanced technical consultancy service, CDR Pompe assists clients in choosing the right setup, ensuring optimal installation, and applying the best failure prevention strategies. Our product range is specifically designed to operate in harsh environments and includes special configurations such as diamond-coated silicon carbide, as well as ongoing development of new materials like zirconium oxide.

Our after-sales service also includes scheduled maintenance and predictive analysis—essential tools for preventing major centrifugal pump issues, minimizing downtime, and ensuring continuous operation.

If you would like a tailored evaluation for your plant, or a quote for a customized system, our experts are ready to help: visit our website and contact us for all the information you need.