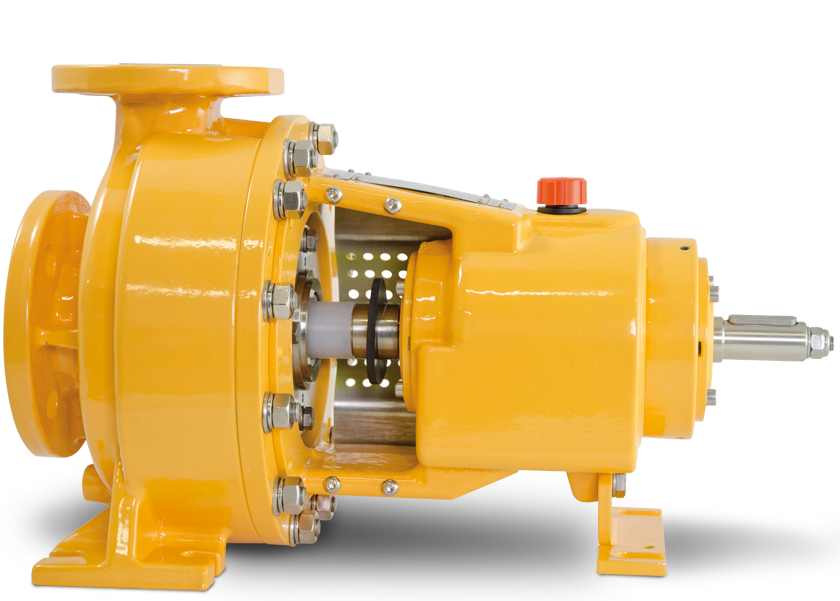

CCL / CCL-B

Plastic Lined Horizontal - Single Stage - Centrifugal pump with Mechanical Seal Lining: PP (Polypropylene)

Long-coupled and Close-coupled executions

Versatility: Suitable for handling corrosive, aggressive and hazardous liquids (low viscosity, clean or slightly to dirty contaminated) in fertilizer processing, biodiesel, general industry, air treatment, waste water treatment and desalination.

Reliability: The CCL offers a wide range of shaft sealing and the pumps are also equipped with reliable bearing bracket, especially developed to be suitable even under heavy duty service.

Design: CCL range shares the same hydraulic design with the UCL series which have been developed focusing on chemical industry’s requests.

TECHNICAL SPECIFICATIONS

| Shaft seal type: | mechanical seal |

|---|---|

| Design: | EN 22858 - ISO 2858 |

| Standard: | ISO 5199 |

| Casing and impeller materials: | PP |

| Impeller type: | closed or open radial |

| Execution: CCL: | long-coupled |

| CCL-B: | close-coupled |

| Flanges: | UNI 1092-2 (ISO 7005-2) PN16RF drilling slotted ANSI150RF |

| Maximum rated pressure @ 20°C: | PN 16 |

| Maximum permissable fluid temperature: | PP: -10°C/+70°C |

| Maximum flow-rate @ 2900 RPM: | 100 m3/h |

| Maximum head @ 2900 RPM: | 68 m |

| Allowable medium viscosity range: | 1 cSt - 60 cSt |

——— More info

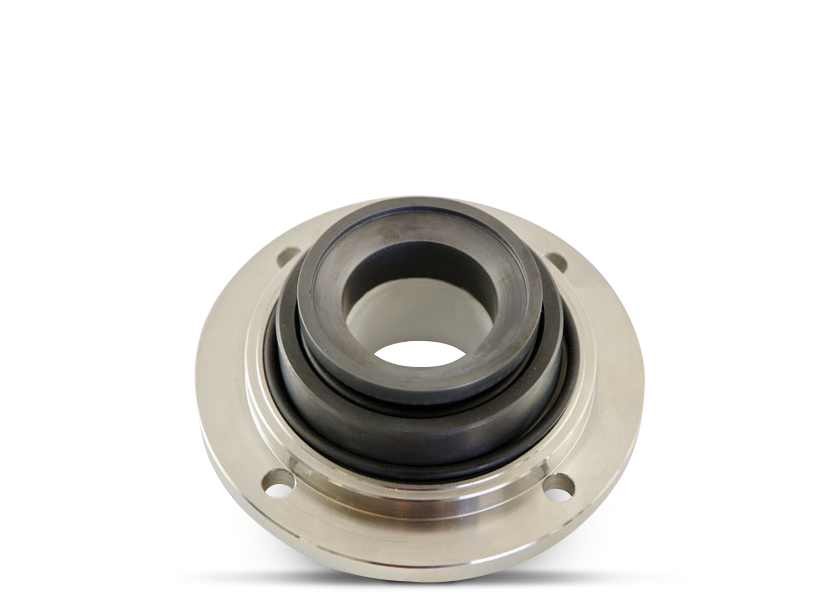

Mechanical Seals

CSE-35

Suitable to work with low/ moderate dirty corrosive liquids. Easy maintenance thanks to the semi-cartridge design. Extremely abrasion-resistant SiSiC seats, no metal parts in contact with the processed liquid and a wide range of options allow the CSE seals to be the best solution for every application. In case of liquid crystallization due to air contact, CDR offers plan 62

TECHNICAL SPECIFICATIONS

| Mechanical seal design: | single mechanical seal |

|---|---|

| Process side materials: | SiSiC |

| Gasket materials: | FPM Viton or EPDM |

| API-PLAN available: | PLAN 02 (CSE-35) and PLAN 02/62 (CSE-35Q) |